กระบวนการตัดการเชื่อมต่อของรีเลย์กำลัง

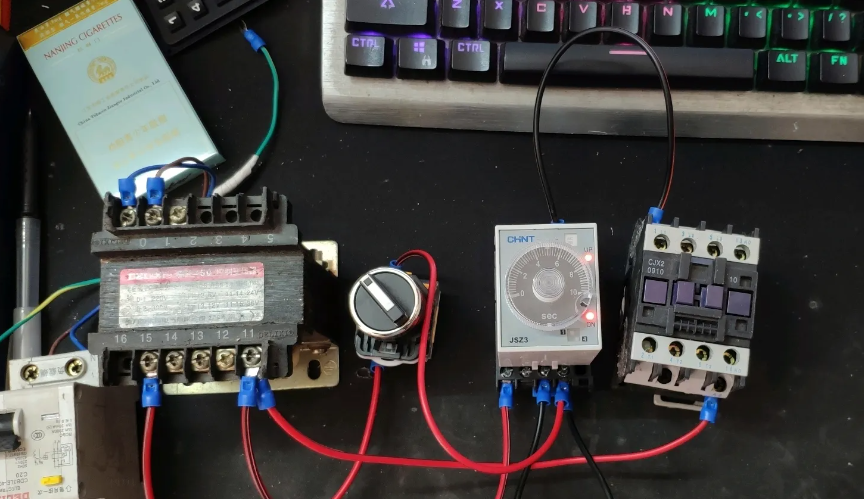

2022-09-15 17:55In production or daily life, we often use certain electrical appliances such as knife switch power relays, contactors, etc. to disconnect the circuit, and we often observe such a phenomenon when disconnecting the circuit: a dazzling spark appears between the contacts, Sometimes it is fleeting, sometimes it lasts for a certain period of time. This is what we usually call a

Everyone has seen an electric welding machine. When it is used for welding, an incandescent dazzling fire will be generated between the electrode and the workpiece, and dazzling sparks will be splashed. This is the arc. The arc is actually a kind of incandescent giant heat that is dissociated from a gas in a neutral state and becomes a large number of charged particles (positive and negative ions and electrons) under the action of circuit voltage and current.” torrent

It can be seen that, to extinguish the arc, we can start from two aspects: on the one hand, weaken and limit the dissociation process, and on the other hand, increase and accelerate the dissociation process. For the former, we usually take the following measures: choose contact materials that are not easy to emit electrons under the action of voltage, current and high temperature; fill the contacts with gas with good arc extinguishing performance or insulation performance (such as nitrogen, nitrogen, sulfur hexafluoride) etc.) or evacuated. For the latter, the following measures can be taken to select contact materials and gas components with good thermal conductivity: ensure a certain breaking distance and breaking speed; adopt some special cooling methods and arc extinguishing devices formed thereby.For electrical appliances such as contactors and automatic switches, since their main task is to switch large-capacity circuits, how to quickly and reliably extinguish the strong arc generated between their contacts has become a key issue. In this type of electrical appliances, in addition to using a certain contact material, contact size and disconnection distance, almost all of them need to use a special arc extinguishing device to strengthen their performance functions. However, in the power relay, its main function is only to respond to the signal. Generally speaking, the capacity of the circuit switched by the specified contact is not large, so the arc is also small. Usually, no special arc extinguishing device is required, and the contact is mainly disconnected. A certain distance to extinguish the arc.Then, when the line voltage and current are constant, how far should the contacts be disconnected to extinguish the arc (without the arc extinguishing device)? Or, what is the line voltage and current that can be cut off by a certain contact opening distance (referred to as contact opening distance)? The solution to this problem mainly relies on experiments.

A large number of experimental studies have shown that for contacts with a certain distance, under certain conditions (that is, when the contact material, atmospheric pressure and composition are constant), the maximum voltage and current values of the circuit that the power relay contacts can break have such a value. Rule: The higher the circuit voltage, the smaller the circuit current that can be interrupted; the lower the circuit voltage, the larger the current that can be interrupted; however, the product of these voltages and currents (that is, power) is basically identical. That is to say, for the contact under the above conditions, the maximum power of the circuit it can open is basically certain. Therefore, people use this power to represent the maximum possible breaking capacity of the contact, and it is called

In addition, the nature of the controlled circuit also has a great influence on the arc extinguishing of the point. Especially when switching inductive loads, the difficulty of arc extinguishing increases because the inductance can prevent the current from decreasing and generate overvoltage. Therefore, the breaking capacity of the same contact when breaking an inductive load is smaller than that when breaking a resistive load. In the technical conditions, the circuit properties and breaking capacity that can be interrupted by the docking point are clearly determined. For example, the Ministry of Four Machines Department's